Chemical Communication

Benefits

Lower Your Costs

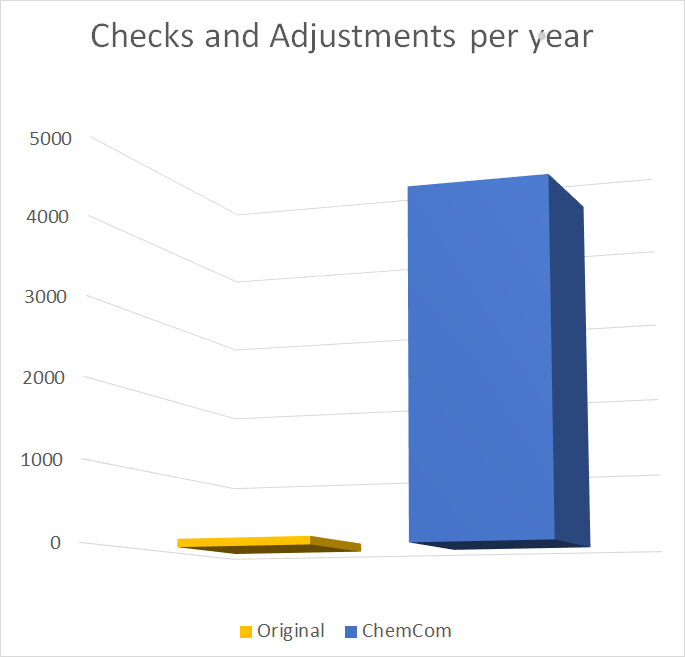

- Coolant usage reduction

- Water usage reduction

- Improve recycling

- Reduce labor hours

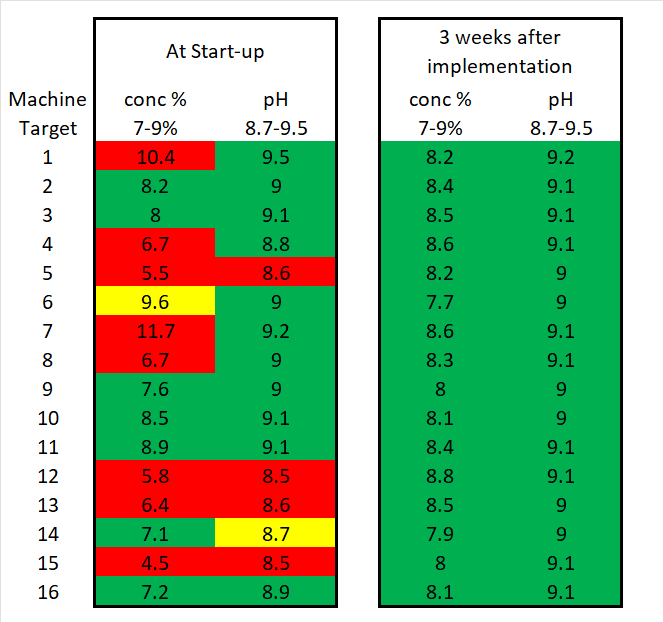

- Provide consistency for production

- Lower scrap rate

- Monitor real time usage by asset

- Improve up-time

- Dial in your tool life~!!

Reduce Your Headaches

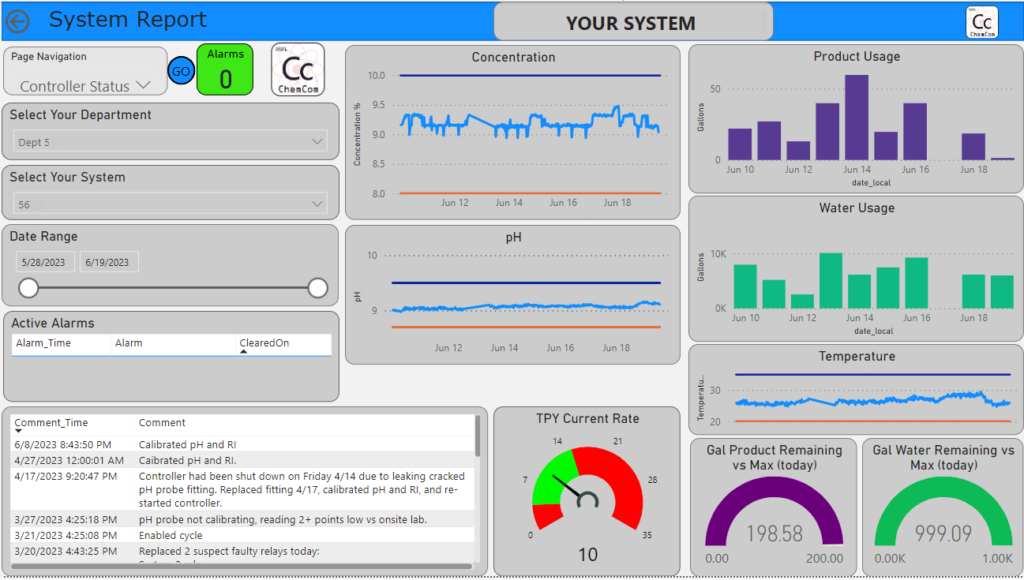

- Dependable concentration control

- 24-7 Monitoring

- Keep track of the data easily

- PowerBI reports that are easy to use

- Communicate reports easily and automatically

- Reduce or eliminate biological excursions

- Get notified for when an issue occurs immediately

- Keep sumps fresher

- Control plan and Auditable.

Enable your:

Engineers

Maintenance

Group

Quality Team

Production Team

Finance / budgeting

Inventory

Control

Chemical Managers

With the Data

That They Need

Improve your process

-

Measure and Control concentration up to 24 machines

-

Automatically top off your machines with water, recycled coolant and/or product.

-

Monitor usage and many other KPIs including pH, temperature, ATP, alkalinity,…. use any sensor you want.

-

Subscribe to alarms and daily reports.

-

Program auxiliary chemical additions to be added at an exact feed rate according to your sump size (biocides for example.)

-

Data is delivered to your phone and your laptop via PowerBI. Data can also be displayed via Ignition or other software.